Psyllium Husk Composition | Complete Chemical and Nutritional Breakdown – 2025

Understanding the psyllium husk composition is essential for anyone seeking to maximize its health benefits or evaluate product quality. The unique chemical structure of psyllium husk – particularly its high mucilage content – explains why this natural fiber delivers such powerful therapeutic effects for digestive health, cholesterol management, and blood sugar control.

This comprehensive guide breaks down the psyllium husk chemical composition at molecular, nutritional, and functional levels. You’ll discover what makes Pakistani psyllium superior, how different compounds contribute to specific health benefits, and why the composition directly determines product efficacy. Whether you’re a health-conscious consumer, nutrition professional, or simply curious about what makes psyllium work, you’ll find scientifically accurate, practical insights into this remarkable plant fiber’s complex structure.

Primary Components of Psyllium Husk Composition

The psyllium husk composition consists of several key components that work synergistically to provide therapeutic benefits.

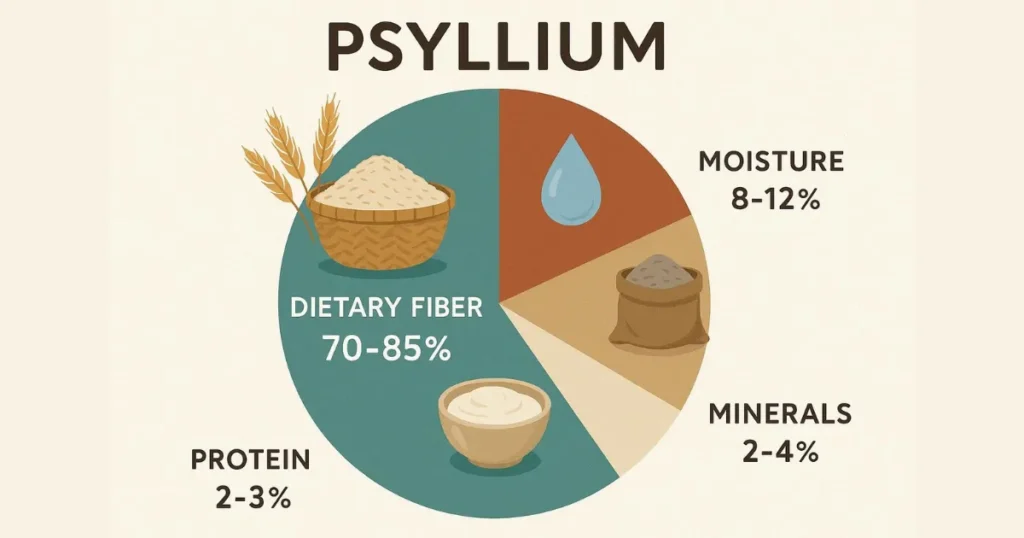

Dietary Fiber (70-85%).

The dominant component is dietary fiber, which breaks down into:

- Soluble fiber: 60-70% of total composition.

- Insoluble fiber: 25-35% of total composition.

- Mucilage: 10-15% (the most therapeutically active component).

This exceptionally high fiber content – representing 70-85% of the husk by weight – makes psyllium one of nature’s most concentrated fiber sources.

Carbohydrates and Polysaccharides.

The fiber component consists primarily of complex carbohydrates:

- Arabinoxylans: The backbone of psyllium’s soluble fiber.

- Rhamnose: A rare sugar present in mucilage.

- Galacturonic acid: Contributes to gel formation.

- Xylose and arabinose: Primary sugar units.

Protein Content (2-3%).

Psyllium husk contains minimal protein:

- Mostly structural proteins in the seed coat.

- Not a significant protein source.

- Negligible impact on therapeutic properties.

Lipids and Fats (Less than 1%).

Fat content is extremely low:

- Primarily fatty acids in the seed coat membrane.

- Contributes minimal calories.

- No significant nutritional fat value.

Minerals and Trace Elements (2-4%).

Small amounts of minerals, including:

- Potassium.

- Calcium.

- Magnesium.

- Phosphorus.

- Trace amounts of iron, zinc, and copper.

Moisture Content (8-12%).

Properly processed and stored psyllium contains:

- 8-10% moisture in optimal storage.

- 12% maximum before quality degradation.

- Lower moisture = longer shelf life.

Understanding this psyllium husk composition helps explain why such small amounts (5-10 grams daily) can produce significant health effects – the concentration of active fiber compounds is remarkably high.

The Chemical Structure of Psyllium Fiber.

Let me explain the psyllium husk chemical composition at the molecular level, which determines its unique therapeutic properties.

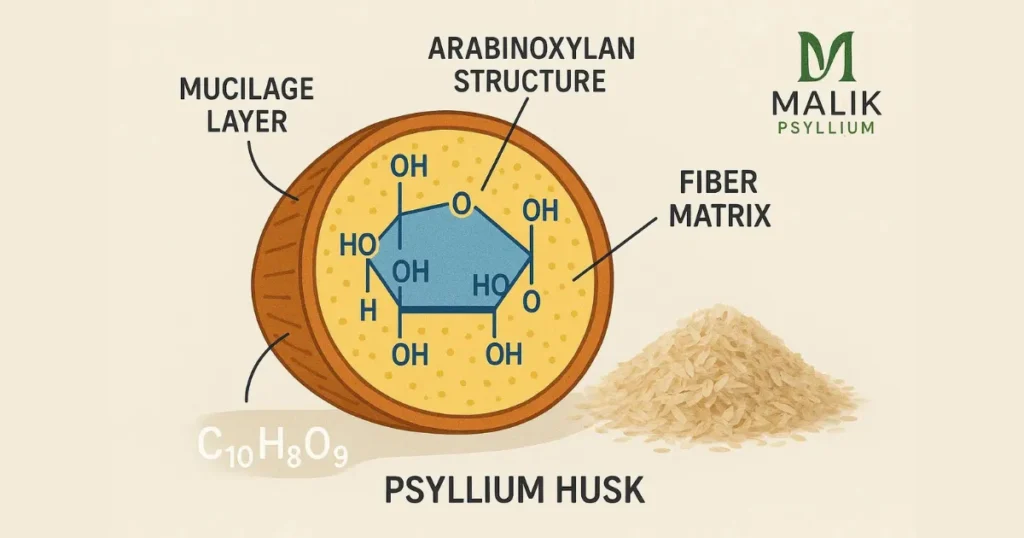

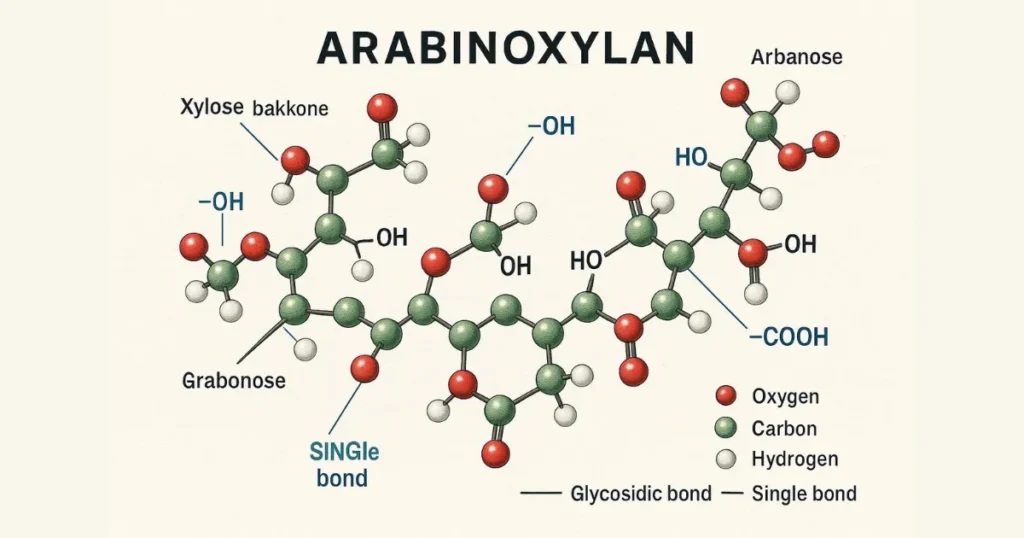

Arabinoxylan Structure.

The soluble fiber consists primarily of arabinoxylans – complex polysaccharides with:

- Backbone: β-(1 → 4) – linked xylose units.

- Side chains: α-L-arabinofuranose residues.

- Branching pattern: Highly branched structure.

- Molecular weight: 200,000-2,000,000 Daltons.

Mucilage Composition.

Mucilage represents the most active component, consisting of:

- Primary sugars: Xylose (58-65%), arabinose (20-25%).

- Minor sugars: Rhamnose (5-8%), galacturonic acid (8-12%).

- Structure: Highly branched, water-soluble polysaccharide.

- Hydration capacity: Expands 10-14 times the original volume.

Pakistani psyllium consistently shows 12-15% mucilage content compared to 8-10% from other regions – this difference significantly impacts therapeutic efficacy.

Glycosidic Bonds.

The chemical bonds linking sugar units include:

- Β-(1 → 4) glycosidic linkages (main chain).

- α-(1 → 2) and α-(1 → 3) branches.

- Resistant to human digestive enzymes.

- Fermentable by colonic bacteria.

Functional Groups.

Key chemical groups affecting behavior:

- Hydroxyl groups (- OH): Enable water binding.

- Carboxyl groups (- COOH): Create a negative charge, bind bile acids.

- Methoxyl groups: Influence viscosity.

- Acetyl groups: Affect gel strength.

Nutritional Composition per Serving.

The psyllium husk composition from a nutritional standpoint shows unique characteristics that make it ideal for health optimization.

Standard serving (1 Tablespoon/ 10 grams).

- Calories: 30-35.

- Total carbohydrates: 8-9 grams.

- Dietary fiber: 7-8 grams.

- Soluble fiber: 3-5 grams.

- Insoluble fiber: 2-3 grams.

- Sugars: Less than 0.5 grams.

- Protein: 0.5-1 gram.

- Fat: Less than 0.5 grams.

- Sodium: 2-5 mg.

- Potassium: 30-40 mg.

Net Carbohydrates.

For individuals tracking carbs (keto, low-carb diets):

- Total carbs: 8-9 grams.

- Minus fiber: 7-8 grams.

- Net carbs: 1-2 grams.

Caloric Density.

Psyllium provides minimal calories because:

- Fiber isn’t fully digested.

- Minimal fat and protein content.

- Sugar content is negligible.

- Most energy comes from short-chain fatty acids produced during fermentation.

Micronutrient Content.

While not a significant source of vitamins or minerals, psyllium contains:

- Vitamin K: Trace amounts.

- B vitamins: Minimal quantities.

- Iron: 0.5-1 mg per serving.

- Calcium: 10-15 mg per serving.

How Composition Determines Therapeutic Effects.

The specific psyllium husk chemical composition directly correlates with its health benefits.

Cholesterol Reduction Mechanism.

The soluble fiber component:

- Binds bile acids in the intestines (via carboxyl groups).

- Prevents bile acid reabsorption.

- Forces liver to use cholesterol for new bile acid synthesis.

- Lowers blood cholesterol by 5-10%.

Blood Sugar Stabilization.

The gel-forming mucilage:

- Slows gastric emptying.

- Creates a physical barrier to glucose absorption.

- Reduces post-meal blood sugar spikes.

- Improves insulin sensitivity over time.

Studies show psyllium’s viscous gel is more effective at glucose control than non-gelling fibers.

Digestive Regularity.

The dual fiber composition:

- Soluble fiber: Softens stool, adds bulk.

- Insoluble fiber: Speeds intestinal transit.

- Mucilage: Lubricates intestinal walls.

- Combined effect: Normalizes consistency.

Prebiotic Effects.

The arabinoxylan structure:

- Resists upper GI digestion.

- Reaches colon intact.

- Fermented by beneficial bacteria.

- Produces short-chain fatty acids (butyrate, propionate, acetate).

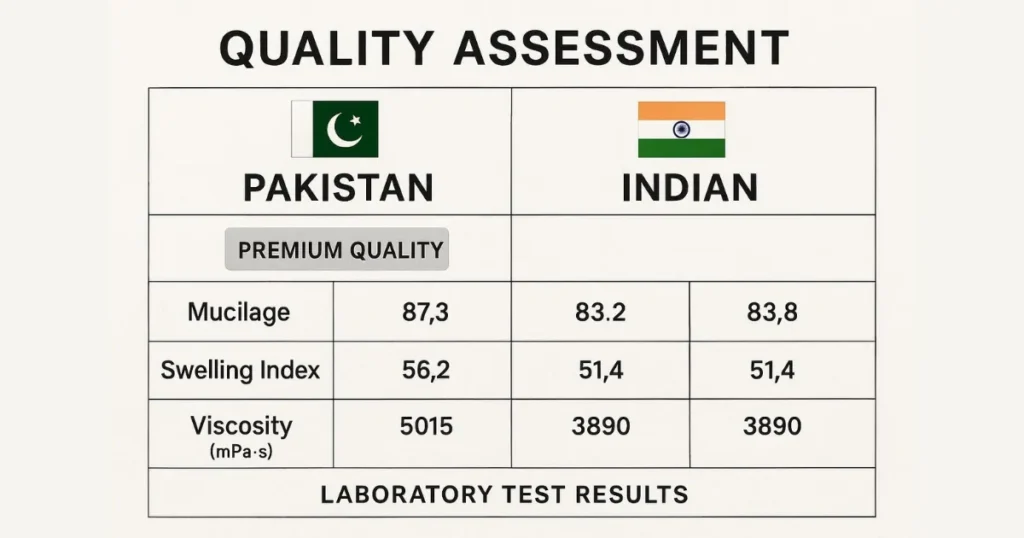

Geographic Variations in Psyllium Composition.

The psyllium husk composition varies significantly based on growing conditions and processing quality.

Pakistani Psyllium Composition.

Pakistan’s Sindh and Punjab regions produce psyllium with:

- Mucilage content: 12-15%.

- Swelling index: 45-55.

- Viscosity: 3,000-4,500 cP (centipoise).

- Purity: 98-99% (in premium grades).

- Fiber density: 75-85% by weight.

These superior specifications result from:

- Ideal soil mineral composition.

- Optimal temperature ranges during the growing season.

- Traditional cultivation knowledge is passed through generations.

- Strict processing and quality control standards.

Indian Psyllium Composition.

Indian psyllium typically shows:

- Mucilage content: 8-10%.

- Swelling index: 35-42.

- Viscosity: 2,000-3,000 cP.

- Purity: 85-95% (varies by supplier).

- Fiber density: 65-75% by weight.

Why Composition Matters.

Higher mucilage content means:

- Stronger gel formation.

- Better therapeutic efficacy.

- More consistent results.

- Lower doses needed for benefits.

At Malik Psyllium, we source exclusively from Pakistan’s premier psyllium growing regions to ensure the highest composition standards.

Factors Affecting Psyllium Husk Composition.

Several variables influence the final psyllium husk chemical composition in commercial products.

Cultivation Factors.

Soil Composition: Mineral-rich soils increase mucilage production. Pakistani soils naturally contain optimal calcium, potassium, and phosphorus ratios.

Climate Conditions:

Hot, dry summers and mild winters maximize mucilage synthesis. Temperature fluctuations during seed development affect polysaccharide branching patterns.

Irrigation Timing:

Water stress at specific growth stages can increase or decrease mucilage content. Traditional Pakistani farmers have perfected irrigation timing over generations.

Harvest Timing:

Seeds harvested at optimal maturity show the highest mucilage percentages. Early or late harvest reduces quality.

Processing Variables.

Cleaning Method:

Mechanical vs. air separation affects purity. Multi-stage cleaning preserves fiber integrity while removing contaminants.

Milling Process:

Grinding temperature and speed impact fiber structure. Excessive heat can degrade mucilage. Cool grinding preserves composition.

Moisture Control:

Proper drying to 8-10% moisture prevents degradation while maintaining composition. Over-drying can damage fiber structure.

Storage Conditions:

Temperature, humidity, and light exposure affect long-term composition stability. Proper storage in cool, dry conditions maintains quality for 24-36 months.

Quality Testing.

Premium manufacturers test for:

- Swelling index: Measures water absorption capacity.

- Viscosity: Determines gel strength.

- Mucilage percentage: Key quality indicator.

- Purity: Identifies adulterants or contaminants.

- Microbial load: Ensures safety.

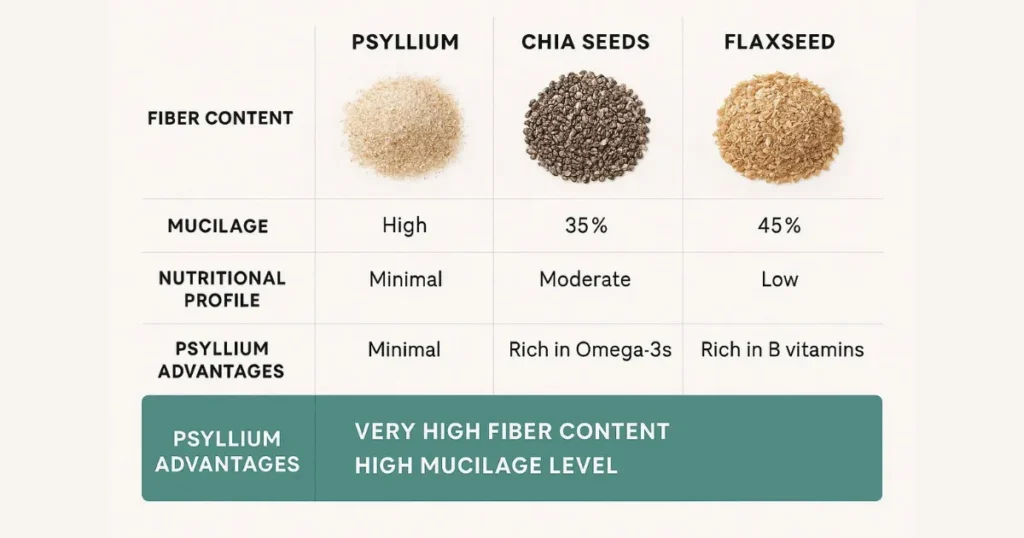

Comparing Psyllium Composition to Other Fibers.

Understanding how psyllium husk composition differs from alternatives highlights its unique advantages.

Psyllium vs. Chia Seeds.

| Component | Psyllium | Chia Seeds |

| Total fiber | 75-85% | 30-35% |

| Soluble fiber | 60-70% | 20-25% |

| Mucilage content | 10-15% | 5-7% |

| Protein | 2-3% | 15-20% |

| Fat | <1% | 30-35% |

| Calories/tbsp | 30-35 | 60-70 |

Psyllium delivers more concentrated fiber with superior gel-forming capacity, while chia provides additional protein and omega-3s but less therapeutic fiber.

Psyllium vs. Flaxseed.

Flaxseed contains:

- Total fiber: 25-30% (much lower).

- Mucilage: 3-6% (inferior gel formation).

- Omega-3s: 20-25% (additional benefit).

- Lignans: Phytoestrogen compounds.

Psyllium vs. Wheat Bran.

Wheat bran composition:

- Total fiber: 40-45%.

- Primarily insoluble (80-90%).

- Minimal soluble fiber (10-15%).

- No mucilage.

- Contains gluten.

Psyllium vs. Inulin.

Inulin characteristics:

- 100% soluble fiber.

- No gel formation.

- Highly fermentable.

- Strong prebiotic effect.

- Can cause significant gas.

The Role of Mucilage in Composition.

Mucilage represents the most therapeutically important component of psyllium husk composition.

What is Mucilage?

Mucilage is a complex, branched polysaccharide that:

- Forms a viscous gel when hydrated.

- Creates protective coating on intestinal walls.

- Binds water, bile acids, and toxins.

- Provides the “slippery” texture of mixed psyllium.

Chemical Structure of Mucilage.

The mucilage molecule consists of:

- Backbone: Linked xylose units.

- Branches: Arabinose, rhamnose, galacturonic acid side chains.

- Functional groups: Carboxyl, hydroxyl, methoxyl groups.

- Molecular weight: Very high (500,000-2,000,000 Daltons).

Mucilage Content as Quality Indicator.

Higher mucilage percentages indicate:

- Superior gel formation.

- Better therapeutic efficacy.

- Premium growing conditions.

- Optimal processing methods.

Pakistani psyllium’s 12-15% mucilage content represents the highest quality available globally, compared to 8-10% from other sources.

Testing Mucilage Content.

Laboratory methods include:

- Swelling index: Measures volume expansion in water.

- Viscosity testing: Quantifies gel strength.

- Chemical extraction: Direct mucilage isolation and weighing.

How Composition Affects Product Forms.

The psyllium husk chemical composition behaves differently in various product forms.

Whole Husk Composition.

Whole husk retains:

- Complete fiber matrix.

- Intact mucilage structure.

- Full nutritional profile.

- Slower hydration rate.

- Larger particle size (0.5-2mm).

Husk Powder Composition.

Grinding creates:

- Smaller particle size (<0.3mm).

- Increased surface area.

- Faster hydration.

- More rapid gel formation.

- Identical chemical composition to whole husk.

Extract Formulations.

Some products use psyllium extracts containing:

- Concentrated mucilage (up to 30%).

- Removed insoluble fiber.

- Enhanced gel-forming capacity.

- Reduced bulk.

Flavored Products.

Commercial flavored psyllium contains:

- Base psyllium husk (70-90%).

- Added sweeteners (sugar or artificial).

- Flavoring agents.

- Sometimes added vitamins or minerals.

Analytical Methods for Composition Testing.

Understanding how the psyllium husk composition is measured helps you evaluate product quality claims.

Standard Testing Protocols

Total Dietary Fiber Analysis (AOAC 985.29)

- Enzymatic-gravimetric method

- Measures both soluble and insoluble fiber

- Considered gold standard

- Results in grams per 100g

Swelling Index Test (IP/BP/USP)

- Measures volume expansion in water

- Quality psyllium: >40 (expands 40+ times)

- Premium psyllium: >45

- Simple, practical quality indicator

Viscosity Measurement

- Uses rotational viscometers

- Measures gel strength at specific concentrations

- Higher viscosity = better therapeutic effect

- Expressed in centipoise (cP)

Mucilage Extraction

- Direct isolation and quantification

- Involves solvent extraction

- Gravimetric determination

- Precise but time-consuming

Purity Testing

- Acid-insoluble ash (measures sand/soil)

- Moisture content

- Foreign matter percentage

- Microbial contamination

Advanced Analytical Techniques

HPLC (High-Performance Liquid Chromatography)

- Separates and quantifies individual sugars

- Determines xylose:arabinose ratio

- Identifies adulteration

- Used in research and premium quality control

NMR Spectroscopy

- Determines molecular structure

- Identifies branching patterns

- Confirms polysaccharide composition

- Research-grade analysis

Gel Permeation Chromatography

- Measures molecular weight distribution

- Higher molecular weight = better quality

- Identifies degradation

- Advanced quality assessment

These analytical methods ensure that labeled composition matches actual product content.

Optimizing Composition through Processing.

Proper processing preserves the psyllium husk composition while enhancing usability.

Harvesting Impact

Timing:

Seeds harvested at 85-90% maturity show optimal composition. Too early = underdeveloped mucilage. Too late = seed shattering and quality loss.

Method:

Mechanical harvesting must avoid excessive damage to seed coats that protect mucilage. Pakistani farmers use specialized equipment calibrated for gentle harvest.

Post-Harvest Handling

Drying:

Controlled drying to 8-10% moisture prevents mold without damaging fiber structure. Temperature must stay below 50°C to preserve mucilage activity.

Storage:

Cool, dry storage in moisture-barrier containers prevents composition degradation. Oxygen absorbers can extend shelf life.

Cleaning and Processing

Multi-Stage Cleaning:

Removes sand, soil, stems, and other plant material without fiber damage. Air separation and sieving preserve husk integrity.

Milling:

For powder production, grinding must be cool (below 40°C) to prevent heat damage to polysaccharides. Stone or hammer mills work best.

Sterilization:

If required, steam sterilization preserves composition better than chemical treatments or irradiation.

Quality Control Checkpoints

Premium manufacturers like Malik Psyllium test composition at multiple stages:

- Raw material upon receipt

- Mid-processing (post-cleaning)

- Final product before packaging

- Periodic stability testing during storage

The Science behind Composition and Health.

Research connecting psyllium husk chemical composition to specific health outcomes validates traditional uses.

Cholesterol Studies.

Clinical trials demonstrate:

- 7-10 grams daily reduces LDL by 5-10%.

- Effect correlates with viscosity (mucilage content).

- Higher mucilage = stronger effect.

- Mechanism: Bile acid binding by carboxyl groups.

Blood Sugar Research.

Studies show:

- Gel formation slows glucose absorption.

- HbA1c reductions of 0.5-1.0% in diabetics.

- Dose-dependent effect related to mucilage content.

- Works best when taken before meals.

Digestive Health Evidence.

Meta-analyses confirm:

- Both constipation and diarrhea improvement.

- Dual-fiber psyllium husk composition enables bidirectional effect.

- Soluble fiber softens, and insoluble fiber speeds transit.

- Superior to single-fiber-type supplements.

Gut Microbiome Studies.

Recent research reveals:

- Arabinoxylan fermentation produces beneficial short-chain fatty acids.

- Increases Bifidobacteria and Lactobacillus populations.

- Reduces pathogenic bacteria.

- Strengthens intestinal barrier function.

What is the psyllium husk composition in terms of fiber content?

Psyllium husk contains 70-85% total dietary fiber, including 60-70% soluble fiber and 25-35% insoluble fiber. The soluble portion consists primarily of mucilage (10-15% in premium grades) made of arabinoxylans. This exceptional fiber density makes psyllium one of nature’s most concentrated fiber sources available.

What is the psyllium husk chemical composition at the molecular level?

Psyllium’s chemical composition consists primarily of branched arabinoxylan polysaccharides with β-(1→4)-linked xylose backbone and arabinose, rhamnose, and galacturonic acid side chains. These molecules contain hydroxyl and carboxyl functional groups that enable water binding and bile acid attachment, creating therapeutic viscous gel formation.

How does mucilage content affect psyllium husk composition quality?

Mucilage content is the primary quality indicator. Premium Pakistani psyllium contains 12-15% mucilage versus 8-10% from other regions. Higher mucilage creates stronger gel formation, better therapeutic efficacy, superior cholesterol reduction, and enhanced blood sugar control. Mucilage percentage directly correlates with swelling index and viscosity measurements.

What nutritional components are in psyllium husk composition?

Per tablespoon (10g): 30-35 calories, 7-8g fiber, 1-2g net carbs, <1g protein, <0.5g fat, minimal vitamins/minerals. Psyllium is valued for concentrated fiber, not micronutrients. The low calorie and net carb content makes it ideal for weight management and ketogenic diets.

Does psyllium husk composition vary by geographic origin?

Yes, significantly. Pakistani psyllium shows 12-15% mucilage, 45-55 swelling index, and 3,000-4,500 cP viscosity. Indian psyllium typically has 8-10% mucilage, 35-42 swelling index, and 2,000-3,000 cP viscosity. Growing conditions, soil composition, and processing methods cause these quality differences.

What makes the arabinoxylan structure in psyllium unique?

Psyllium’s arabinoxylans have highly branched structures with side chains creating three-dimensional networks when hydrated. This branching pattern provides maximum surface area for water binding and bile acid attachment. The specific glycosidic bonds resist digestive enzymes but allow colonic fermentation, providing prebiotic benefits.

How is psyllium husk composition tested for quality?

Standard tests include: total dietary fiber analysis (AOAC 985.29), swelling index (>40 for quality products), viscosity measurement (centipoise), mucilage extraction, purity assessment (acid-insoluble ash <2%), and microbial testing. Advanced methods include HPLC for sugar composition and NMR spectroscopy for molecular structure.

Can processing methods change psyllium husk composition?

Processing affects physical form but not chemical composition if done properly. Grinding whole husk into powder maintains identical fiber content while increasing surface area for faster hydration. However, excessive heat (>50°C), improper storage, or contamination can degrade mucilage activity and reduce therapeutic effectiveness over time.

Conclusion.

The psyllium husk composition – particularly its exceptional 70-85% fiber content, 12-15% mucilage in premium grades, and unique arabinoxylan structure – explains why this natural fiber source delivers such powerful therapeutic benefits. Understanding the psyllium husk chemical composition at molecular, nutritional, and functional levels empowers you to make informed product choices and maximize health outcomes.

Pakistani psyllium from the Sindh and Punjab provinces consistently demonstrates superior composition with higher mucilage percentages, better gel-forming capacity, and greater therapeutic efficacy compared to alternatives from other regions. This quality advantage stems from ideal growing conditions, generations of cultivation expertise, and rigorous processing standards that preserve the delicate polysaccharide structures responsible for psyllium’s health benefits.

When evaluating psyllium products, prioritize composition verification through third-party testing, mucilage content specifications, swelling index values, and origin documentation. The chemical structure and nutritional profile directly determine product effectiveness – higher quality composition translates to better health results with lower doses needed.

Whether you’re managing cholesterol, optimizing blood sugar control, improving digestive regularity, or supporting gut microbiome health, understanding psyllium’s composition helps you select products that deliver genuine therapeutic value rather than just marketing claims.

Malik Shabbir

Featured Blogs

Isabgol Ke Fayde – Psyllium Husk Ke Poori Science-Based Rahnumayi – 2026

Isabgol ke fayde jaanna aaj ke daur mein zyada zaroori

Isabgol Benefits in Hindi | Psyllium Husk Ke Fayde, Sahi Upyog Aur Savdhaniyan – 2026

Agar aap isabgol benefits in hindi mein samajhna chahte hain,