How is Psyllium Husk Made | From Seed to Supplement | Complete Production Guide – 2025

Ever wondered how is psyllium husk made from a tiny seed into the powerful fiber supplement that supports digestive health worldwide? The journey from field to finished product involves careful cultivation, precise harvesting, and specialized processing techniques that preserve the therapeutic properties of this remarkable plant fiber.

Understanding what psyllium husk is made from – the outer coating of Plantago ovata seeds – and the production methods that transform raw material into premium fiber supplements helps you appreciate quality differences and make informed purchasing decisions. This comprehensive guide walks you through every stage of psyllium production, from soil preparation in Pakistan’s prime growing regions through final quality testing, revealing why production methods directly impact the fiber’s therapeutic effectiveness and purity.

What Psyllium Husk is made From: The Source Plant

Before explaining how is psyllium husk made, let me clarify what is psyllium husk made from at the botanical level.

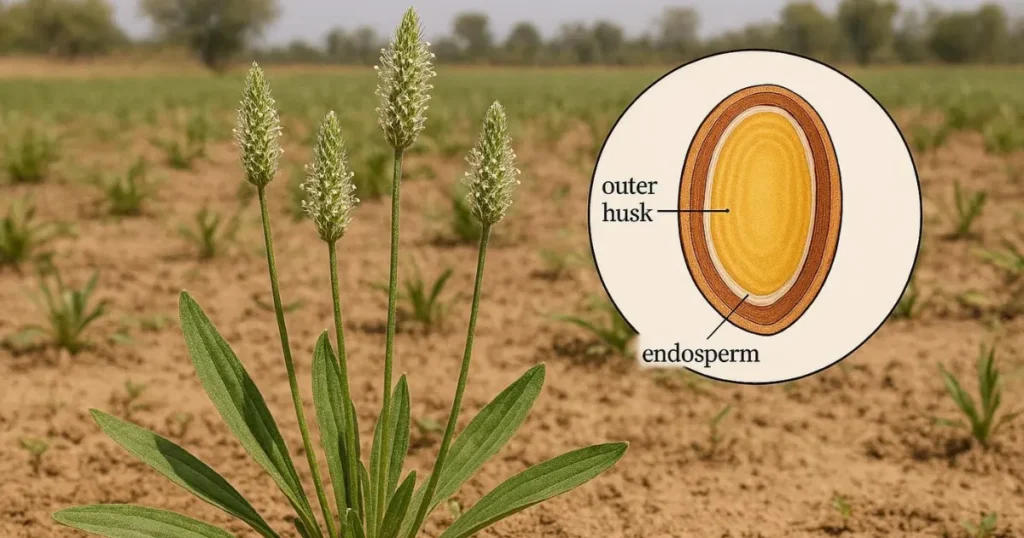

The Source: Plantago ovata

Psyllium husk comes from Plantago ovata, a medicinal plant in the Plantaginaceae family. This annual herb grows 12-18 inches tall with narrow leaves and produces small flower spikes containing tiny seeds.

The Seed Structure

Each Plantago ovata seed consists of:

- Outer husk: The therapeutically valuable part, rich in mucilage

- Inner endosperm: Contains some fiber but less mucilage

- Embryo: The germinating part (removed during processing).

The husk represents only about 25-30% of the total seed weight but contains 70-85% of the therapeutic fiber, including the crucial mucilage that provides health benefits.

Why the Husk Matters.

The husk’s outer layers contain:

- High concentrations of soluble fiber (60-70%).

- Mucilage content of 10-15% in premium grades.

- Arabinoxylan polysaccharides that form therapeutic gel.

- Minimal calories, protein, or fat.

This specific composition makes the husk far more valuable therapeutically than the whole seed or inner components.

Geographic Origins.

While Plantago ovata originated in the Mediterranean and Persian regions, commercial cultivation today centers in:

- Pakistan: 80% of global premium production (Sindh and Punjab provinces).

- India: Secondary production (primarily Gujarat state).

- Iran: Limited traditional cultivation.

- Other regions: Minimal commercial production.

Pakistan’s climate and soil conditions produce psyllium with the highest mucilage content globally – typically 12-15% compared to 8-10% elsewhere.

Stage 1: Cultivation and Growing Psyllium.

Understanding how is psyllium husk made begins with proper cultivation practices that maximize fiber quality.

Soil Preparation.

Premium psyllium cultivation requires:

- Soil type: Well-drained sandy loam with pH 7.0-8.0.

- Tillage: Multiple plowings to create fine seedbed.

- Organic matter: Incorporation of well-rotted manure.

- Leveling: Precise grading for uniform water distribution.

Pakistani farmers have perfected these techniques over generations, understanding how soil preparation affects mucilage development.

Planting Process.

Timing: Seeds are planted in late October to early November when temperatures drop below 30°C. This timing is critical – too early causes heat stress, too late reduces yield.

- Seed Rate: 4-6 kg per hectare, broadcast or drilled in rows 20-25 cm apart.

- Depth: Seeds planted 2-3 cm deep in moist soil for optimal germination.

- Spacing: Proper density ensures adequate air circulation while maximizing yield.

Growing Conditions.

Optimal growth requires:

- Temperature: Cool nights (10-15 ° C), warm days (20-25 ° C).

- Water: Moderate irrigation – 3-4 irrigations total.

- Sunlight: Full sun exposure for 6-8 hours daily.

- Growing period: 110-130 days from planting to harvest.

Pakistan’s winter climate in Sindh and Punjab provinces provides these ideal conditions naturally.

Crop Management.

Weed Control:

Manual weeding or selective herbicides in early growth stages. Weeds compete for nutrients and reduce yield quality.

Pest Management:

Monitoring for aphids, cutworms, and fungal diseases. Pakistani farmers use integrated pest management to minimize chemical use.

Fertilization:

Moderate nitrogen, phosphorus, and potassium application. Excessive nitrogen reduces mucilage content.

Irrigation Timing:

Critical water application at flowering and seed development stages maximizes mucilage production.

Stage 2: Harvesting Psyllium Seeds.

Proper harvesting techniques are crucial in how psyllium husk is made with maximum quality retention.

Determining Harvest Readiness.

Multiple indicators signal optimal harvest timing:

- Seed maturity: 85-90% of seeds turn brown.

- Moisture content: Seeds contain 12-15% moisture.

- Plant color: Lower leaves yellow, upper stems dry.

- Seed firmness: Seeds resist thumbnail pressure.

Harvesting too early yields immature seeds with lower mucilage. Harvesting too late causes seed shattering and field losses.

Harvesting Methods.

Traditional Manual Harvesting:

- Plants cut by hand with sickles.

- Bundled and left to dry in the field.

- Labor-intensive but gentle on seeds.

- Still used for premium quality lots.

Mechanical Harvesting:

- Specialized combines adjusted for small seeds.

- Settings calibrated to minimize husk damage.

- Faster and more economical.

- Requires skilled operators to maintain quality.

Pakistani farmers often combine both methods – mechanical for the main harvest, manual for premium quality selections.

Post-Harvest Handling.

Immediately after harvest:

- Field drying: Bundled plants are left for 3-5 days if the moisture is high.

- Threshing: Separating seeds from plant material.

- Initial cleaning: Removing large debris, stems, leaves.

- Moisture reduction: Natural or mechanical drying to 8-10%.

Proper post-harvest handling prevents mold growth and preserves mucilage activity.

Quality Considerations.

Premium harvest practices include:

- Harvesting during dry weather.

- Avoiding soil contamination.

- Gentle handling to prevent husk damage.

- Quick processing to prevent degradation.

- Separate handling of premium and standard grades.

These practices directly impact the final psyllium husk quality you purchase.

Stage 3: Seed Cleaning and Preparation.

This critical stage in how is psyllium husk made determines final product purity.

Multi-Stage Cleaning Process.

Stage 1 – Primary Cleaning:

- Removes large debris (stems, leaves, stones).

- Uses screens and air separation.

- Reduces foreign matter by 70-80%.

Stage 2 – Fine Cleaning:

- Removes sand, soil particles, and broken seeds.

- Uses vibrating screens with specific mesh sizes.

- Air blowers remove light impurities.

- Gravity tables are separate by density.

Stage 3 – Polishing:

- Final cleaning removes dust and fine particles.

- Aspiration removes remaining light materials.

- Results in clean, uniform seeds ready for processing.

Quality Testing.

Between cleaning stages, samples are tested for:

- Purity percentage: Target 98-99% for premium grades.

- Moisture content: Should be 8-10%.

- Foreign matter: Less than 1%.

- Damaged seeds: Minimal breakage.

- Sand content: Below 0.5%.

At Malik Psyllium, we test every batch at multiple checkpoints to ensure pharmaceutical-grade purity.

Storage of Clean Seeds.

Clean seeds are stored in:

- Cool, dry warehouses (below 25°C).

- Moisture-controlled environments.

- Pest-proof containers.

- Protected from light exposure.

Proper storage prevents quality degradation before processing.

Stage 4: Husk Separation – The Critical Process.

This stage is the heart of how psyllium husk is made – separating the valuable husk from the seed core.

Milling Process.

Initial Milling:

- Seeds pass through specialized mills.

- Gentle crushing breaks seed coats without pulverizing.

- Multiple mill passes with different gap settings.

- Temperature controlled (below 40°C) to preserve mucilage.

Separation Techniques.

Air Classification:

- Streams of controlled air separate light husks from heavier seed cores.

- Multiple stages with different air velocities.

- Most common method in modern facilities.

- Preserves husk integrity while achieving high purity.

Sieving Method:

- Uses vibrating screens with specific mesh sizes.

- Separates based on particle size.

- Often combined with air classification.

- Requires multiple screen sizes for complete separation.

Gravity Separation:

- Uses density differences between husk and seed.

- Inclined tables with controlled vibration.

- Effective for removing remaining seed particles.

- Final polishing step.

Achieving High Purity.

Reaching 98-99% purity requires:

- Multiple separation passes.

- Continuous quality monitoring.

- Removal of intermediate fractions.

- Re-processing of mixed-grade material.

Lower-quality producers may stop at 85-95% purity, including more seed material and reducing fiber concentration.

Particle Size Control.

For husk powder production:

- Additional fine milling after separation.

- Controlled grinding to achieve a consistent particle size.

- Cool grinding to prevent heat damage.

- Sieving to ensure uniform texture.

- Whole husk skips this step, maintaining larger particle sizes (0.5-2mm).

Stage 5: Quality Control and Testing.

Comprehensive testing ensures the final product meets therapeutic standards.

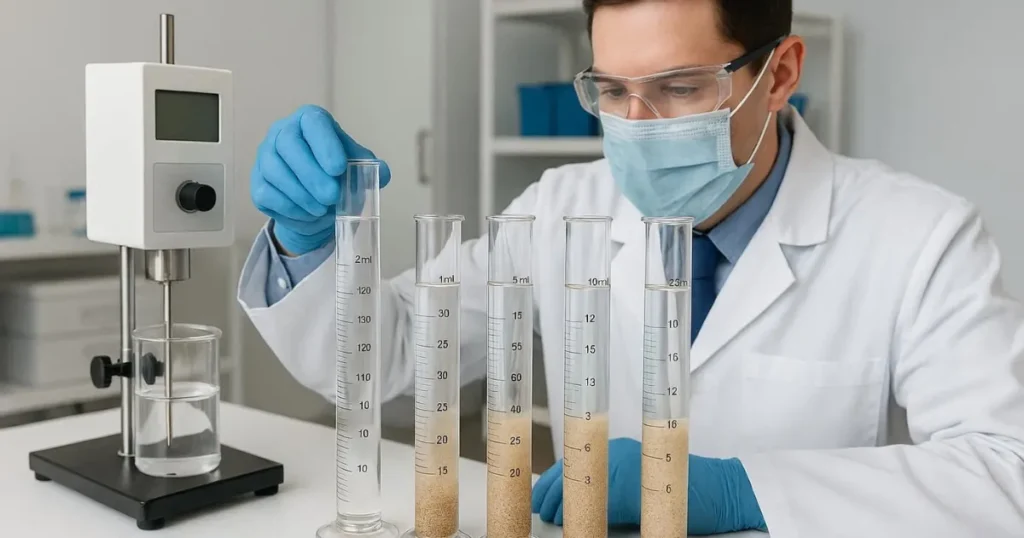

Physical Testing.

Swelling Index:

- Measures water absorption capacity.

- Quality psyllium exceeds 40 (swells 40 + times).

- Premium Pakistani psyllium reaches 45-55.

- Direct indicator of mucilage content.

Viscosity Measurement:

- Tests gel strength using viscometers.

- Higher viscosity= better therapeutic effect.

- Pakistani psyllium: 3,000-4,500 centipoise.

- Lower quality: 2,000-3,000 centipoise.

Particle Size Analysis:

- Ensures consistency in powder products.

- Affects mixing properties and gel formation.

- Standardized for batch-to-batch uniformity.

Chemical Testing.

Fiber Content Analysis:

- AOAC Method 985.29 for total dietary fiber.

- Separate soluble and insoluble fiber quantification.

- Verifies labeled fiber content accuracy.

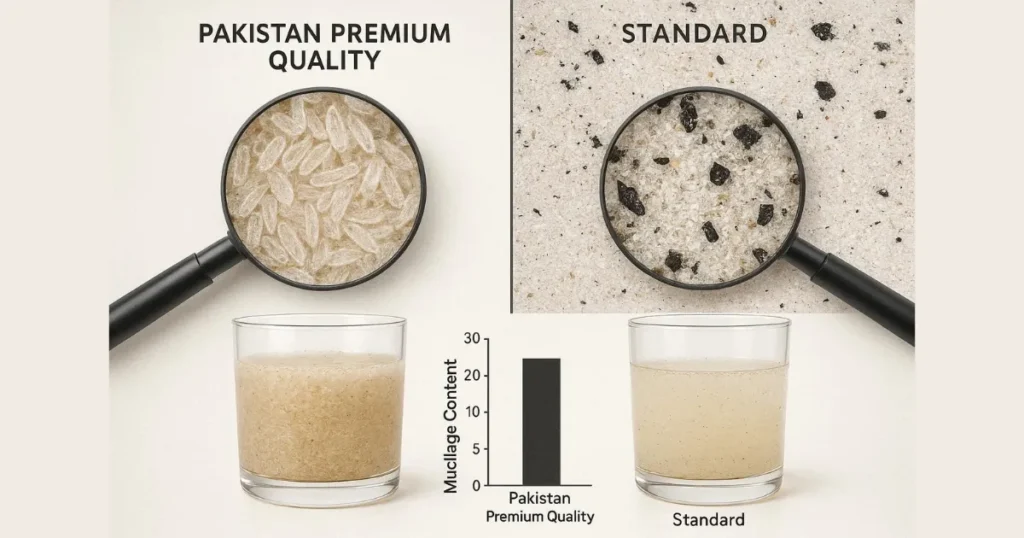

Mucilage Content:

- Direct extraction and measurement.

- Premium grades: 12-15%.

- Standard grades: 8-10%.

- Key quality differentiator.

Moisture Content:

- Must be 8-10% for stability.

- Higher moisture risks mold growth.

- Lower moisture can indicate over-processing.

Purity Assessment.

Acid-Insoluble Ash:

- Measures sand and soil content.

- Should be below 2% for quality products.

- Below 1% for pharmaceutical grade.

Foreign Matter:

- Visual inspection and microscopic analysis.

- Identifies seed particles, plant material, and insects.

- Premium products: < 1% foreign matter.

Microbiological Testing.

Essential safety tests include:

- Total plate count: Bacteria levels.

- Yeast and mold: Fungal contamination.

- E. coli: Fecal contamination indicator.

- Salmonella: Pathogen presence.

- Staphylococcus aureus: Specific pathogen.

All tests must meet FDA, European Pharmacopoeia, and international standards.

Heavy Metal Screening.

Testing for:

- Lead, arsenic, mercury, cadmium.

- Agricultural chemicals and pesticides.

- Ensures safety for human consumption.

Stage 6: Packaging and Storage.

Proper packaging preserves quality from the production facility to the end consumer.

Packaging Materials.

Bulk Commercial Packaging:

- Multi-wall paper bags with polyethylene lining.

- Typically 25-50 kg capacity.

- Moisture-barrier properties essential.

- Labeled with batch numbers and test results.

Retail Consumer Packaging:

- HDPE bottles or pouches with zip seals.

- Moisture-resistant, food-grade materials.

- Opaque or dark-colored to block light.

- Tamper-evident seals for safety.

Storage Requirements.

Packaged psyllium requires:

- Cool storage (below 25°C).

- Humidity control (below 60%).

- Protection from direct sunlight.

- Pest-proof facilities.

- Good air circulation.

Shelf Life.

Properly packaged and stored:

- Whole husk: 24-36 months.

- Husk powder: 18-24 months.

- Consumer packages: 18-24 months after opening.

Expiration dates are based on stability testing showing maintained swelling index and microbial safety.

How Production Methods Affect Quality.

Different production approaches create significant quality variations in how psyllium husk is made.

Premium Production (Pakistani Standard).

Characteristics:

- Selective harvest timing for maximum mucilage.

- Gentle mechanical processing to preserve husk integrity.

- Multi-stage cleaning for 98-99% purity.

- Temperature-controlled throughout.

- Comprehensive testing at multiple checkpoints.

- Results: 12-15% mucilage, swelling index 45-55.

Standard Commercial Production.

Characteristics:

- Less selective harvest timing.

- Faster, more aggressive processing.

- Fewer cleaning stages, 85-95% purity.

- Less temperature control.

- Basic quality testing.

- Results: 8-10% mucilage, swelling index 35-42.

Cost vs. Quality Trade-offs.

Premium production costs 20-40% more but delivers:

- 30-50% higher mucilage content.

- Better therapeutic efficacy.

- More consistent batch quality.

- Longer shelf life.

- Superior gel formation.

When purchasing bulk psyllium husk, the production method justifies price differences.

Common Questions about Psyllium Production.

Why is Geographic Origin Important?

Pakistan’s Sindh and Punjab provinces provide:

- Ideal temperature ranges (cool winters, hot summers).

- Specific soil mineral composition.

- Generations of cultivation expertise.

- Established quality control infrastructure.

These factors combine to produce consistently superior mucilage content.

How Long Does Production Take?

From planting to packaged product:

- Growing period: 110-130 days.

- Drying and storage: 7-15 days.

- Processing and cleaning: 1-3 days.

- Quality testing: 2-5 days.

- Total: Approximately 4-5 months.

Can Psyllium Be Produced Organically?

Yes, but with challenges:

- Requires certified organic fields.

- Limited pest control options.

- Potentially lower yields.

- Higher production costs.

- Similar final quality if done properly.

Organic certification relates to farming practices, not necessarily superior therapeutic properties.

What Happens to By-Products?

The seed cores separated from husks are:

- Used as animal feed (high protein content).

- Processed for oil extraction.

- Composted for organic matter.

- No part goes to waste.

Innovation in Psyllium Production.

Modern advances improve how psyllium husk is made while preserving traditional quality.

Processing Technology.

Recent improvements include:

- Optical sorting machines that detect and remove defects.

- Advanced air classification systems with better separation.

- Real-time moisture monitoring during processing.

- Automated quality testing equipment.

Quality Assurance.

Modern facilities employ:

- HACCP (Hazard Analysis Critical Control Points).

- ISO 22000 food safety management.

- Good Manufacturing Practices (GMP).

- Blockchain traceability from field to consumer.

Sustainability Initiatives.

Progressive producers focus on:

- Water conservation in cultivation.

- Solar energy for processing facilities.

- Waste reduction and recycling.

- Fair labor practices and farmer support.

These innovations maintain product quality while improving efficiency and sustainability.

Identifying Quality in Finished Products.

Knowing how psyllium husk is made helps you evaluate product quality.

Visual Indicators.

Quality psyllium shows:

- Color: Light blonde to pale beige (not dark brown).

- Texture: Fine, consistent (if powder); uniform pieces (if whole husk).

- Purity: No visible seeds, stems, or debris.

- Smell: Mild, slightly nutty aroma (not musty or sour).

Performance Indicators.

Quality products demonstrate:

- Rapid gel formation when mixed with water (30-60 seconds).

- Smooth, viscous gel texture.

- Complete hydration without clumping.

- Minimal settling after mixing.

Label Information.

Look for products specifying:

- Botanical name (Plantago ovata).

- Origin country (Pakistan for premium).

- Purity percentage (98%+ is ideal).

- Fiber content per serving.

- Batch numbers and testing.

Premium manufacturers provide this transparency because they’re proud of their production methods.

The Difference Production Quality Makes.

Two products, both labeled “psyllium husk”, can perform very differently based on how psyllium husk is made.

Clinical Efficacy.

High-quality production delivers:

- Stronger cholesterol reduction (5-10% vs. 3-5%).

- Better blood sugar control.

- More reliable digestive effects.

- Consistent results across batches.

User Experience.

Premium processing provides:

- Easier mixing without clumps.

- Better taste and texture.

- Less gas and bloating.

- Faster results.

Economic Value.

While premium products cost more per unit:

- You need smaller doses for equivalent effects.

- More consistent results mean less waste.

- Longer shelf life reduces spoilage.

- Better therapeutic outcomes justify the cost.

Understanding production helps you evaluate true value rather than just comparing prices.

How is psyllium husk made from the seed?

Psyllium husk is made by harvesting Plantago ovata seeds, drying them to 8-10% moisture, cleaning thoroughly, then gently milling and separating the outer husk from the inner seed using air classification, sieving, and gravity separation. Multiple processing stages achieve 98-99% purity in premium products.

What is psyllium husk made from originally?

Psyllium husk is made from the outer coating (seed husk) of Plantago ovata plants grown primarily in Pakistan’s Sindh and Punjab provinces. The husk represents 25-30% of seed weight but contains 70-85% of therapeutic fiber, including valuable mucilage that provides health benefits.

How long does it take to make psyllium husk?

Complete production takes 4-5 months: 110-130 days growing, 7-15 days drying/storage, 1-3 days processing/cleaning, and 2-5 days quality testing. The growing season runs from October through February in Pakistan’s optimal climate conditions that maximize mucilage development.

Why does Pakistan produce the best psyllium husk?

Pakistan’s Sindh and Punjab regions provide ideal conditions: cool winters with warm days, specific soil mineral composition, and generations of cultivation expertise. Pakistani psyllium consistently shows 12-15% mucilage content versus 8-10% elsewhere, producing superior gel formation and therapeutic efficacy.

What processing methods preserve psyllium quality?

Quality-preserving methods include: gentle milling below 40 ° C, multi-stage air classification for separation, temperature-controlled processing, rapid drying after harvest, moisture-proof storage, and comprehensive testing at multiple checkpoints. Premium producers prioritize these methods despite higher costs.

Can you make psyllium husk at home?

Technically, yes, but impractical. You’d need Plantago ovata seeds, 4-5 months growing time, specialized milling equipment, air separation systems, and quality testing capabilities. Commercial production achieves 98-99% purity, impossible with home methods. Purchasing quality products is more practical and cost-effective.

What determines psyllium husk purity levels?

Purity depends on cleaning thoroughness, separation efficiency, and processing stages. Premium 98-99% purity requires multi-stage cleaning, precise air classification, and quality monitoring. Standard 85-95% purity uses fewer processing steps, leaving more seed material and reducing fiber concentration per gram.

How is psyllium husk powder different from whole husk?

Both start identically, but powder undergoes additional fine milling after husk separation. Cool grinding (below 40 ° C) prevents mucilage degradation while creating smaller particles (< 0.3 mm vs. 0.5-2mm for whole husk). Powder hydrates faster and forms a more viscous gel; whole husk absorbs more slowly.

Conclusion.

Understanding how psyllium husk is made – from careful cultivation in Pakistan’s prime agricultural regions through specialized harvesting, multi-stage processing, and rigorous quality testing – reveals why not all psyllium products deliver equivalent therapeutic benefits. The journey from Plantago ovata seed to purified fiber supplement involves dozens of critical decisions affecting mucilage content, purity, and therapeutic efficacy.

What psyllium husk is made from – the outer coating of carefully cultivated seeds – matters less than how it’s produced. Premium production methods that emphasize gentle processing, temperature control, multi-stage purification, and comprehensive testing create products with 12-15% mucilage content compared to 8-10% from standard production. This quality difference translates directly to superior health benefits, more consistent results, and better value despite higher initial costs.

Pakistani psyllium production, particularly from Sindh and Punjab provinces, represents the global gold standard due to ideal growing conditions, generations of cultivation expertise, and sophisticated processing infrastructure. When selecting psyllium products, prioritize those specifying origin, purity levels, and quality testing documentation. The production process determines whether you receive a pharmaceutical-grade therapeutic fiber or merely a commodity product marketed as psyllium.

By understanding the complete production process, you can make informed purchasing decisions that prioritize quality, efficacy, and safety over simple price comparisons.

Malik Shabbir

Featured Blogs

Isabgol Ke Fayde – Psyllium Husk Ke Poori Science-Based Rahnumayi – 2026

Isabgol ke fayde jaanna aaj ke daur mein zyada zaroori

Isabgol Benefits in Hindi | Psyllium Husk Ke Fayde, Sahi Upyog Aur Savdhaniyan – 2026

Agar aap isabgol benefits in hindi mein samajhna chahte hain,